The Startup Chronicles: Energy Monitoring, Tight Budgets, and Even Tighter Deadlines.

Once upon a time, I joined a startup. Our mission? To conquer the world—well, at least the world of Building Energy Monitoring. You know, because saving on energy bills is the new world domination. Despite our small team, we somehow managed to snag a few big clients. Things were looking up!

At the same time, I was knee-deep in electrical engineering studies, because clearly, sleep was optional. We had some early wins with software, but we needed to take the next step: hardware. Why? Because gathering data from buildings was key, and paying for existing solutions wasn’t going to happen on our "budget." So, we decided to roll up our sleeves and build it ourselves. Obviously.

The Dream Device: Because What’s One More Prototype?

Our target audience? Large public buildings with those fancy Building Management Systems (BMS)—places spending a small fortune just to keep everything at a "comfortable" 22°C. From our previous work, we knew it was possible to cut their energy expenses by 15% with very little effort (and no one loves "very little effort" more than a big company). We also knew the key protocols and interfaces to tap into these systems.

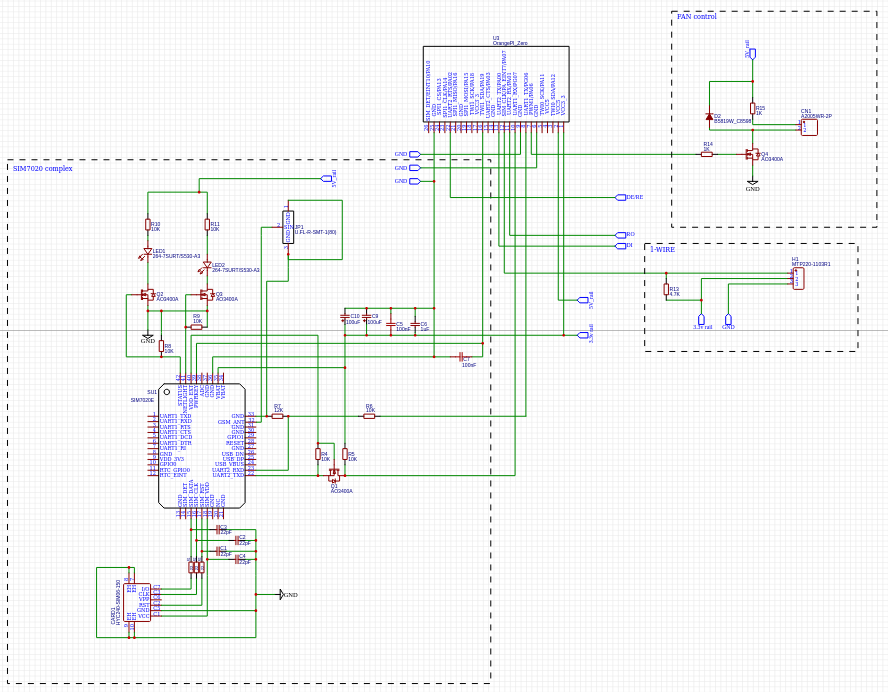

So, here’s what our miracle device needed to do:

- 12-24V power support – The standard in automation. We’re not here to reinvent the wheel.

- M-Bus interface – The universal language of metering devices. Like English, but with less grammar.

- Modbus/RS485 interface – The go-to for automation systems. If you don’t speak this, you’re out of the conversation.

- GSM connectivity – Because dealing with corporate IT departments is like asking a sloth to run a marathon.

- Ethernet connector – For the rare moments when internet access isn’t a bureaucratic nightmare.

- Cheap – These devices were meant to charm potential clients, so we needed them to be so affordable, you’d think they were party favors.

- Linux support – Our small team needed to move fast. Linux gave us access to libraries, tools, and, well, sanity.

- Overcurrent protection – Because nothing says “we tried” like an overheated circuit.

The Ingenious Plan: Modular Magic

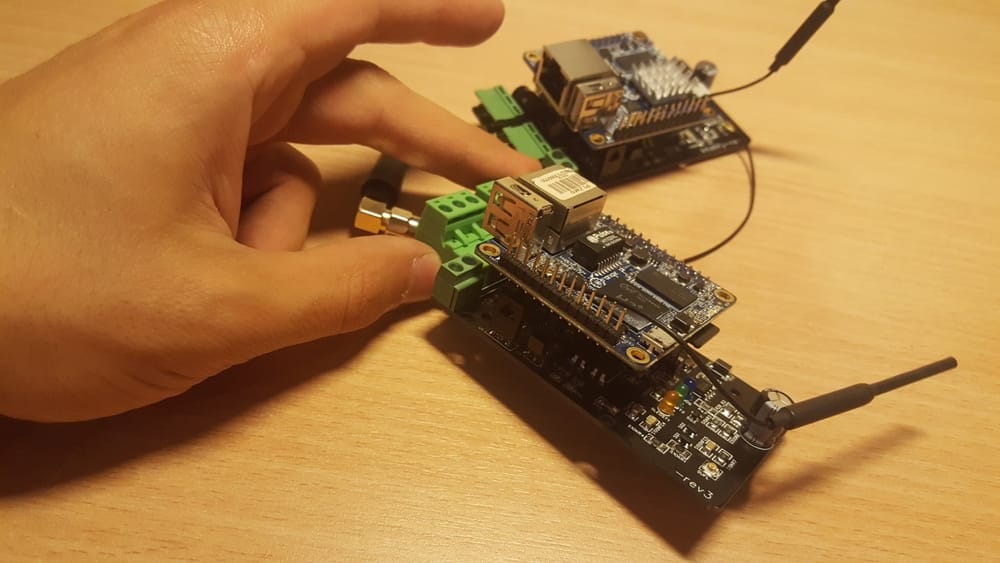

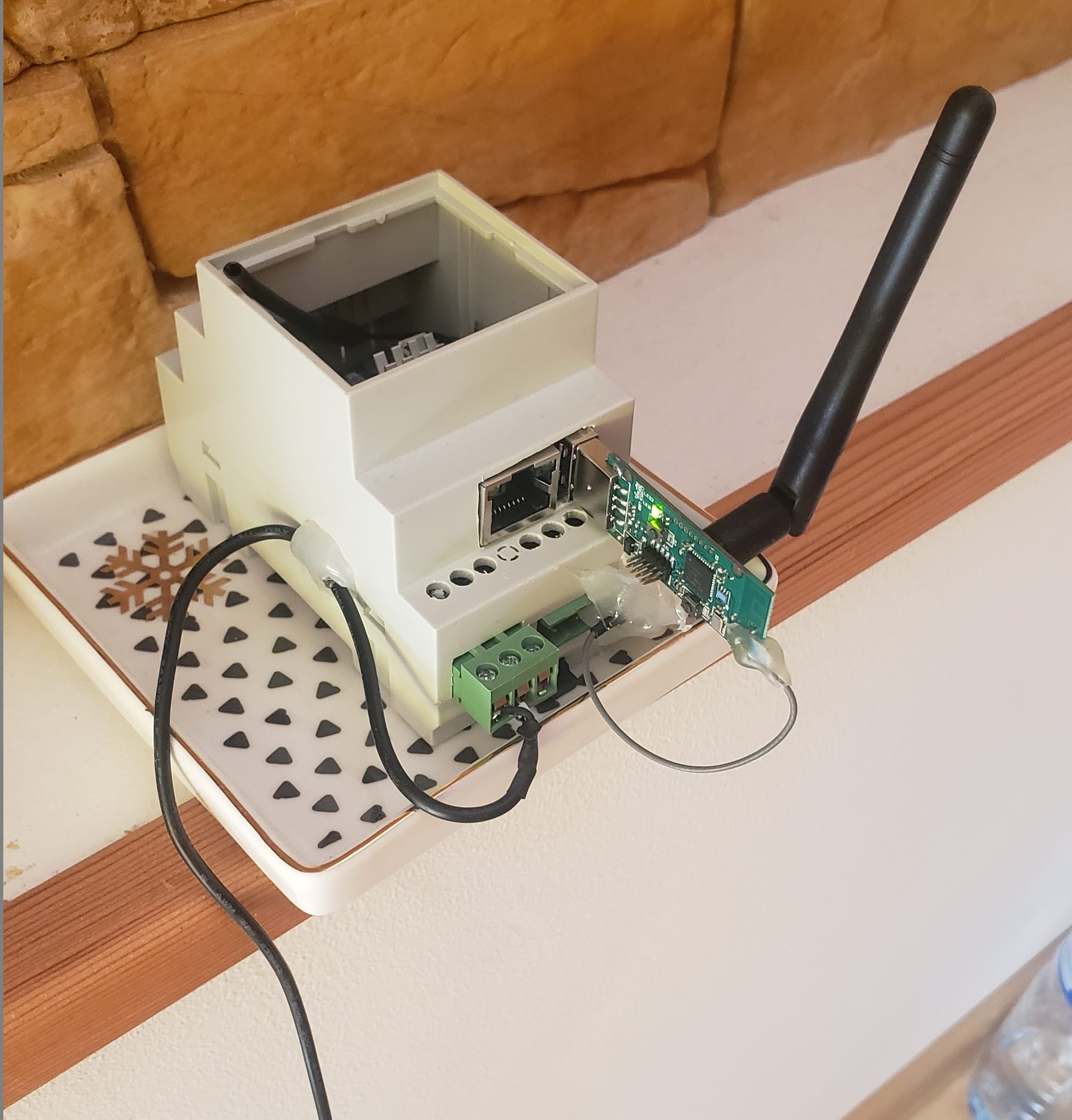

The solution was simple—modular design. Two parts:

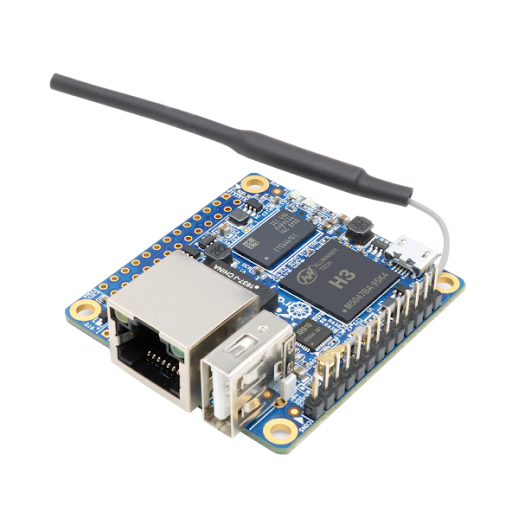

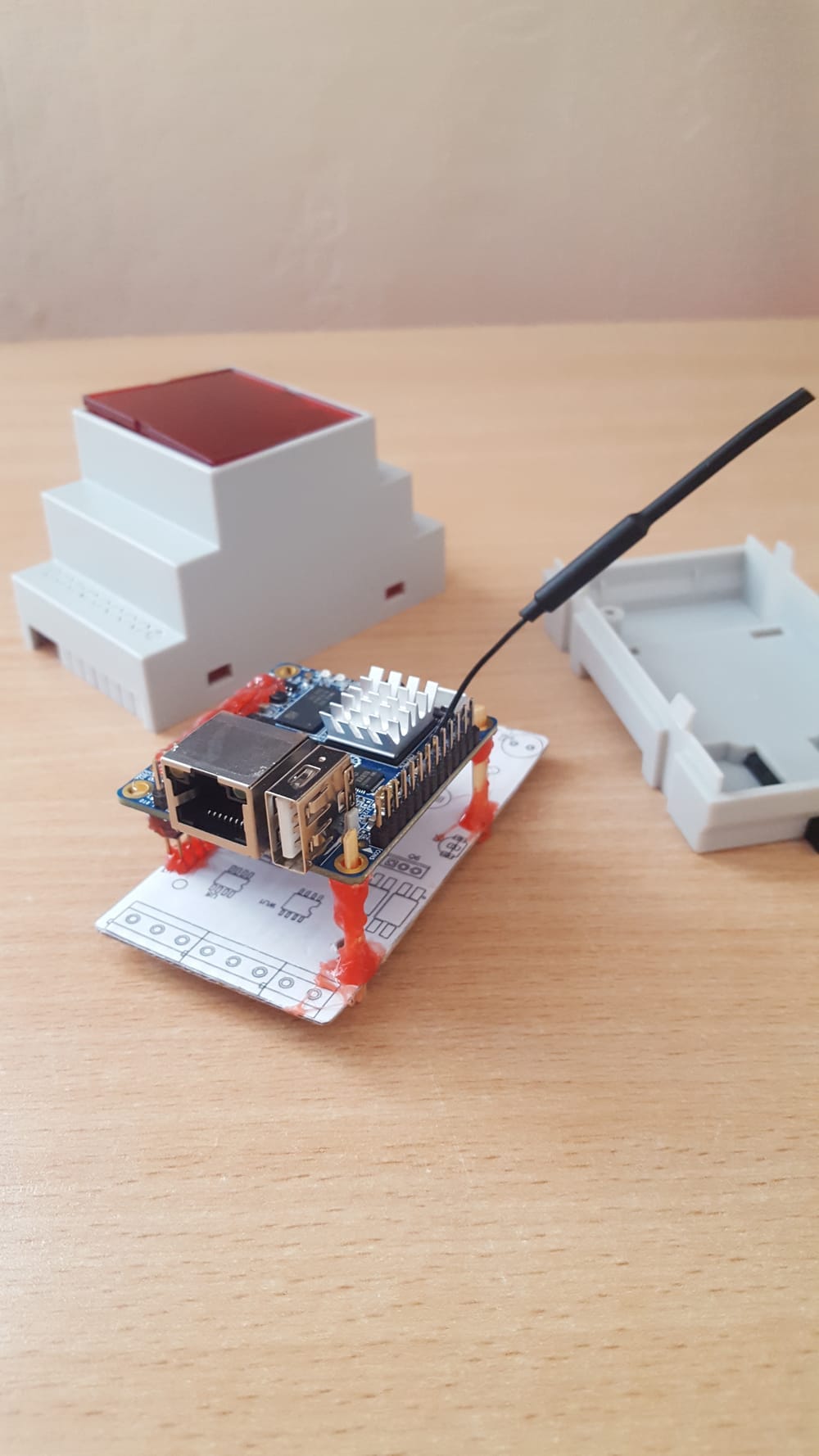

- The Brain – An Orange Pi Zero, because Raspberry Pi is too mainstream. This little computer, costing about €30, ran Armbian OS with solid updates. Six years later, it’s still around, which is more than can be said for some tech startups. Check it out here.

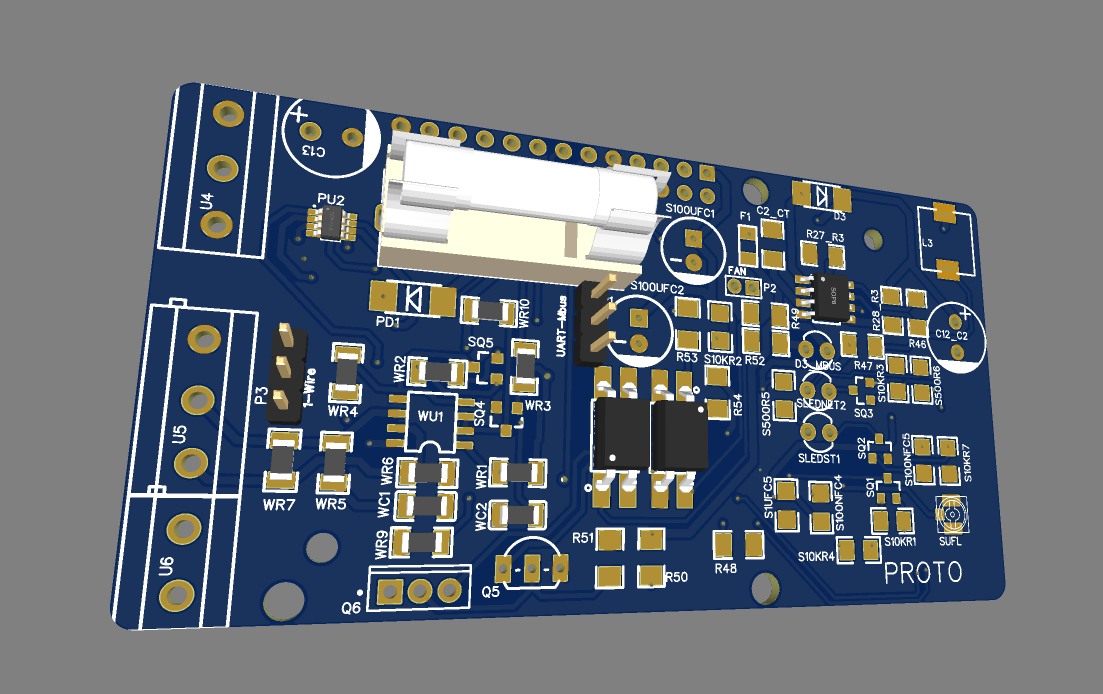

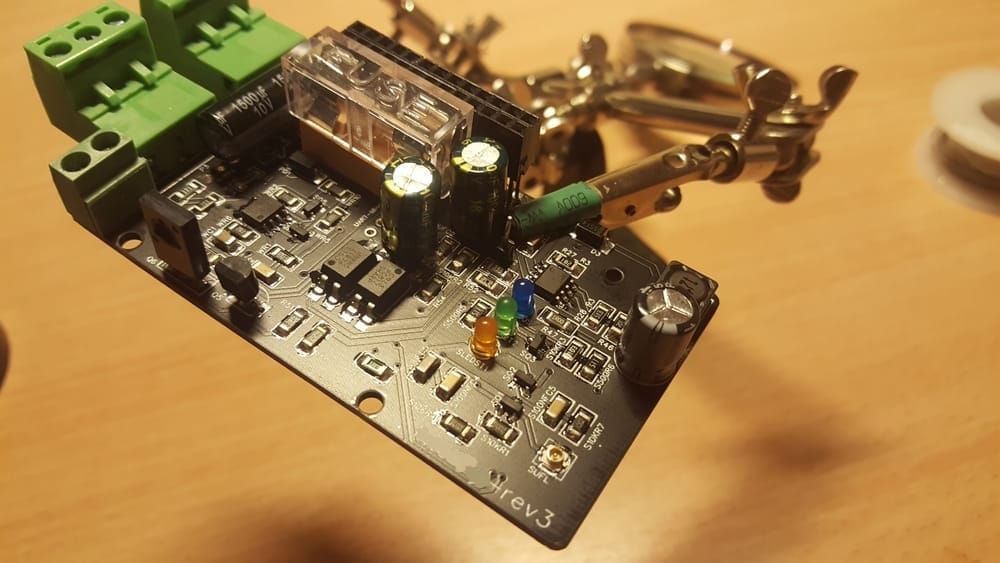

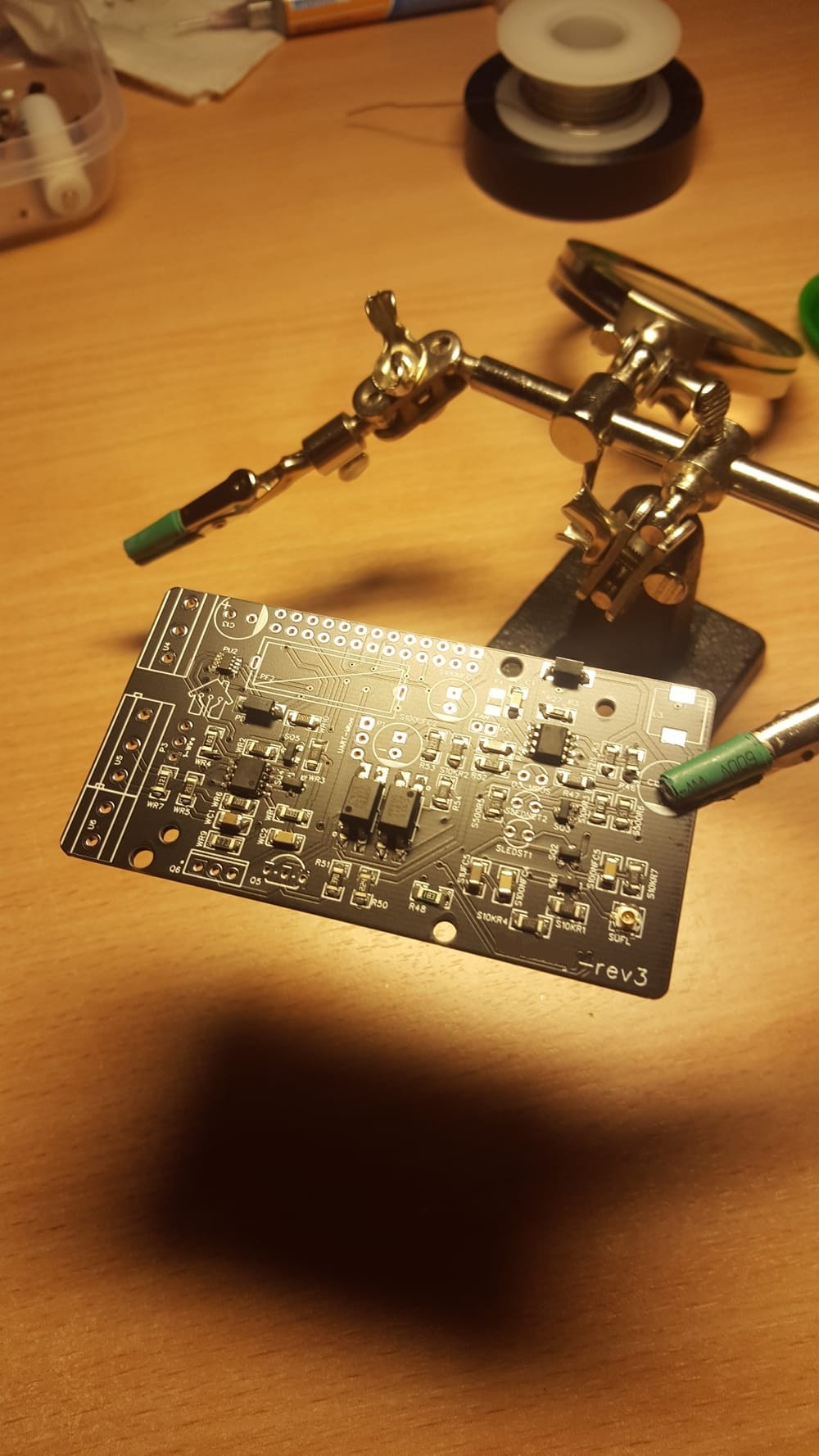

- The Interface Board – A custom PCB that connected the brain to everything else: RS485, M-Bus, SIM module, voltage converters, LED indicators, and so on. Essentially, everything to make it look complicated enough to impress someone in a boardroom.

Success! Well, Sort Of…

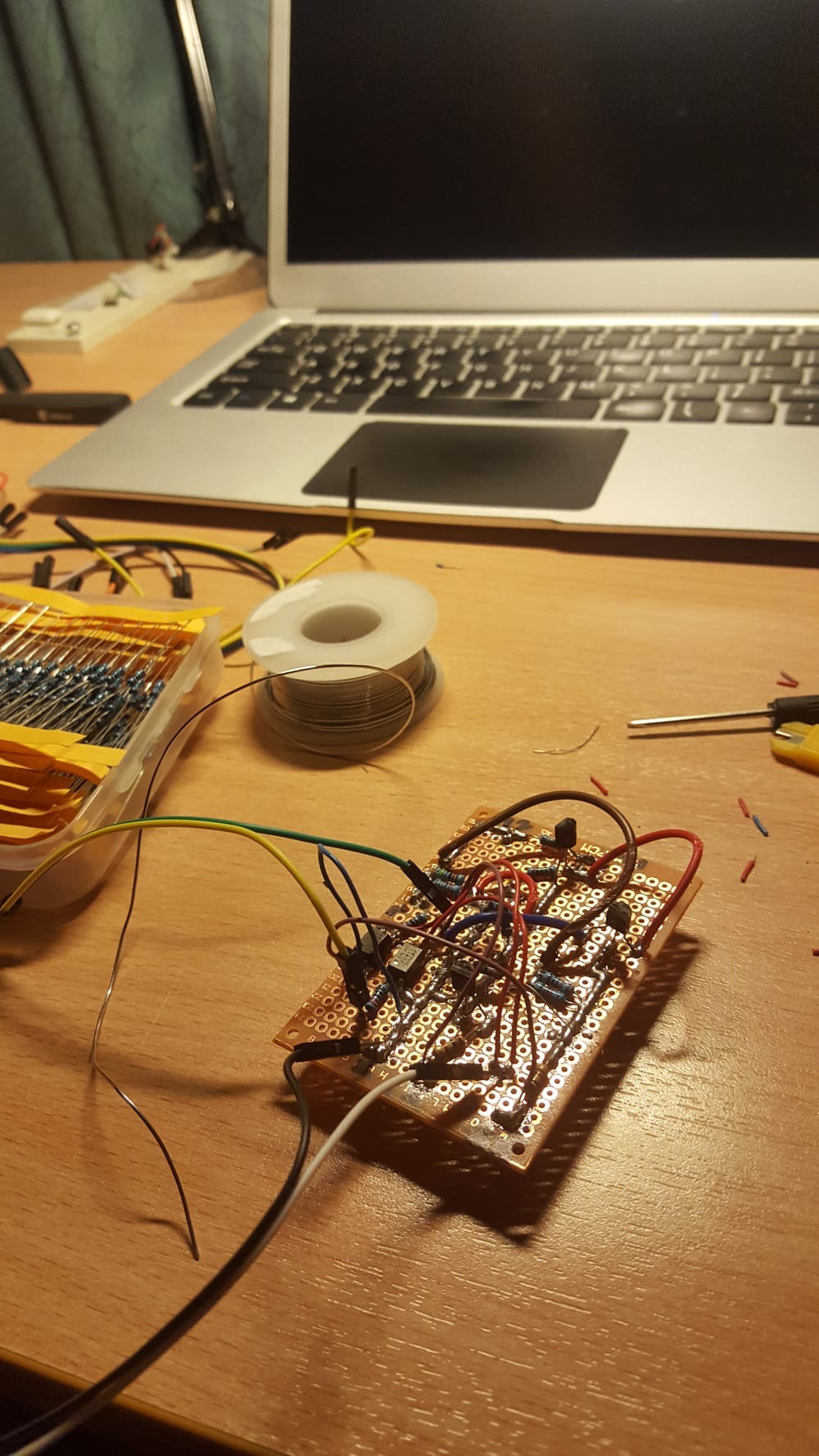

I designed a few boards, ordered them from JLCPCB, and assembled them. Surprisingly, they worked (mostly). But as any good startup story goes, our budget was tighter than a jar lid your grandmother sealed. So, we didn’t make it past the prototype stage.

For fun, I installed one of the prototypes in my parents’ house as a Zigbee hub, for monitoring temperature. That was four years ago. I recently found it, still running. It felt a bit like finding an old pet rock—nobody needed it anymore, but there it was, quietly doing its job.

The Here and Now: Same Spirit, New Problem

Fast forward to today. My latest problem? I can’t control my pellet boiler remotely. Naturally, instead of buying something off the shelf, I’ve decided to hack a solution together. Because if I can build an energy monitoring device on a shoestring budget, surely fixing this boiler will be a piece of cake.

Stay tuned.

![IOT hub [part 1 of 3]](/blog/content/images/size/w1200/2024/10/Selection_007.png)